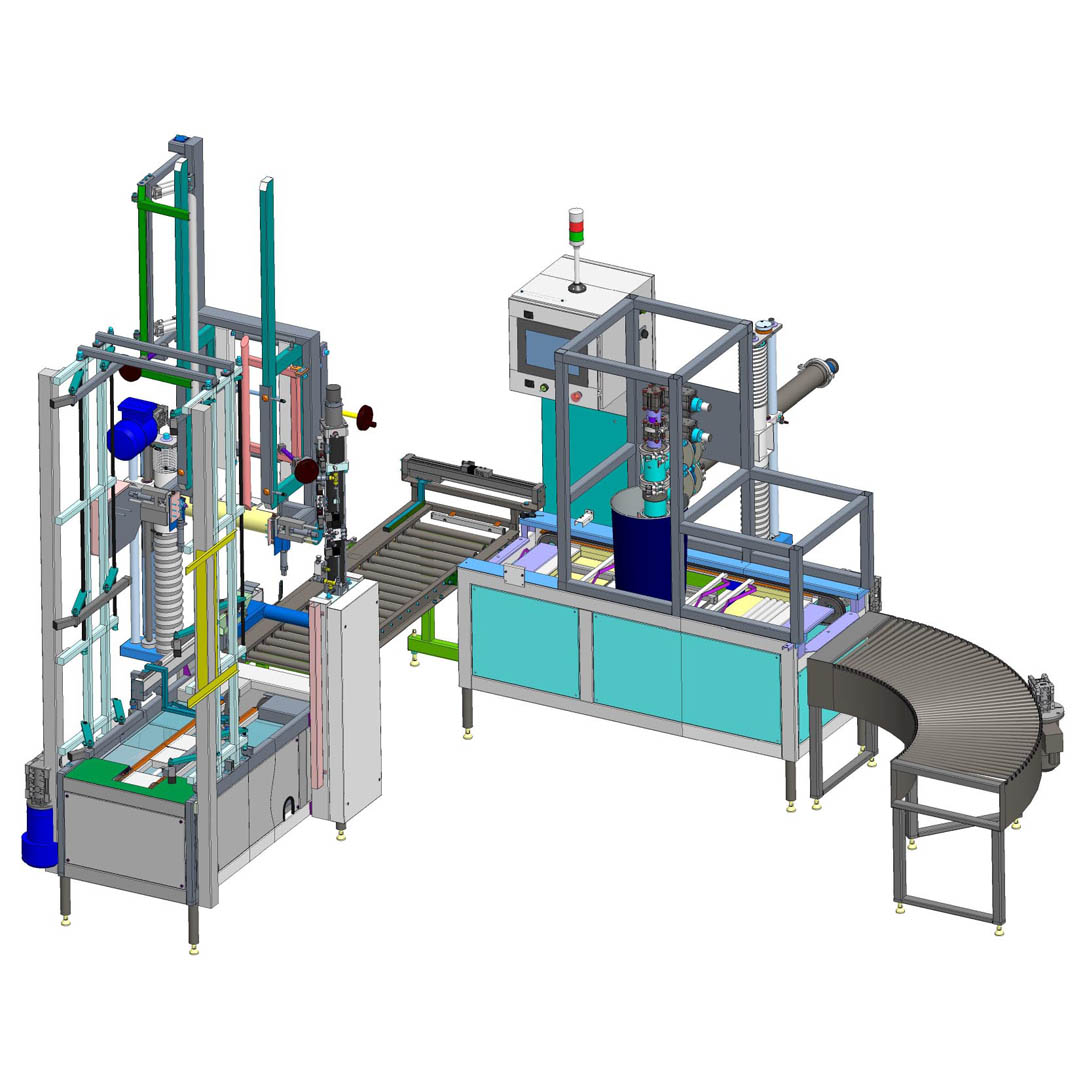

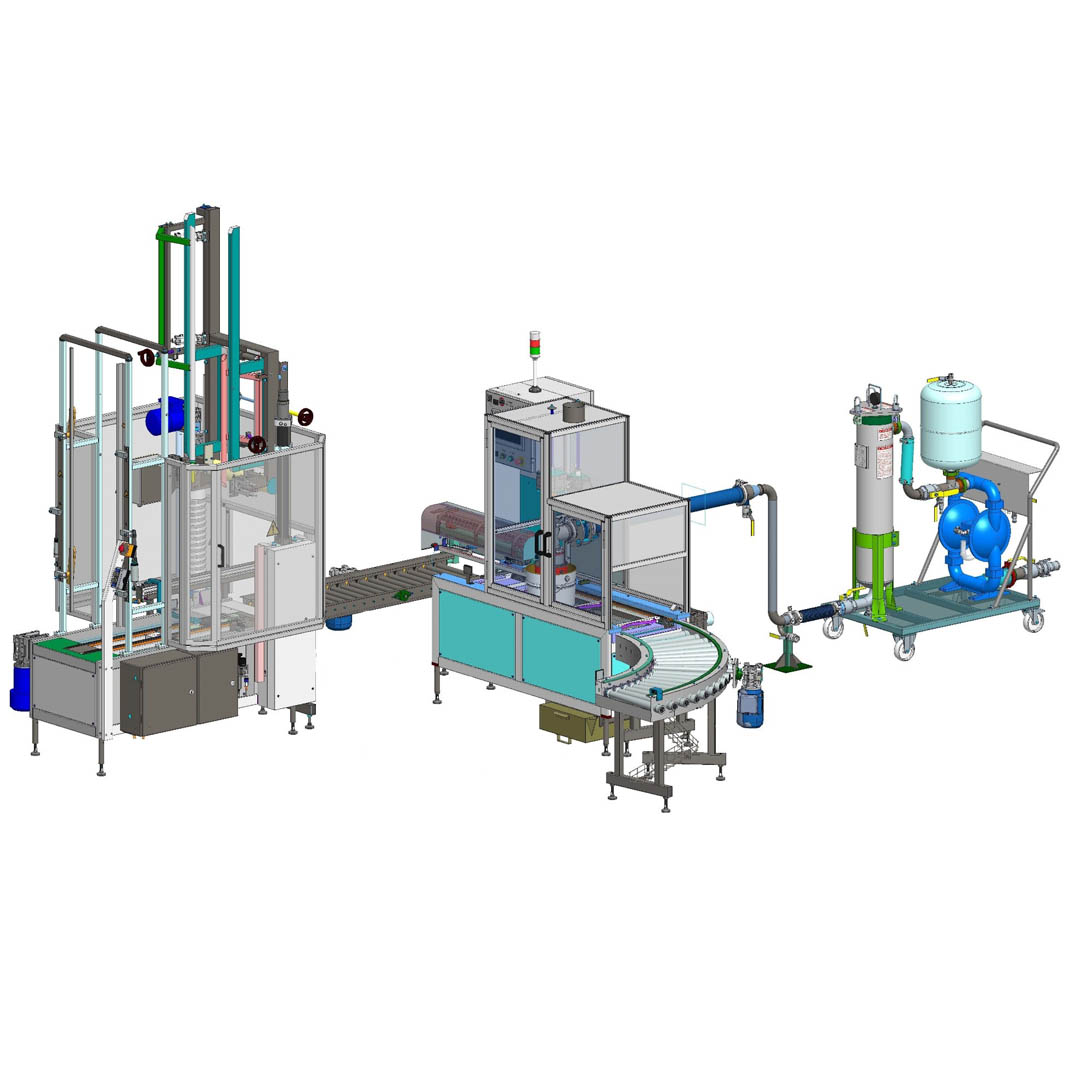

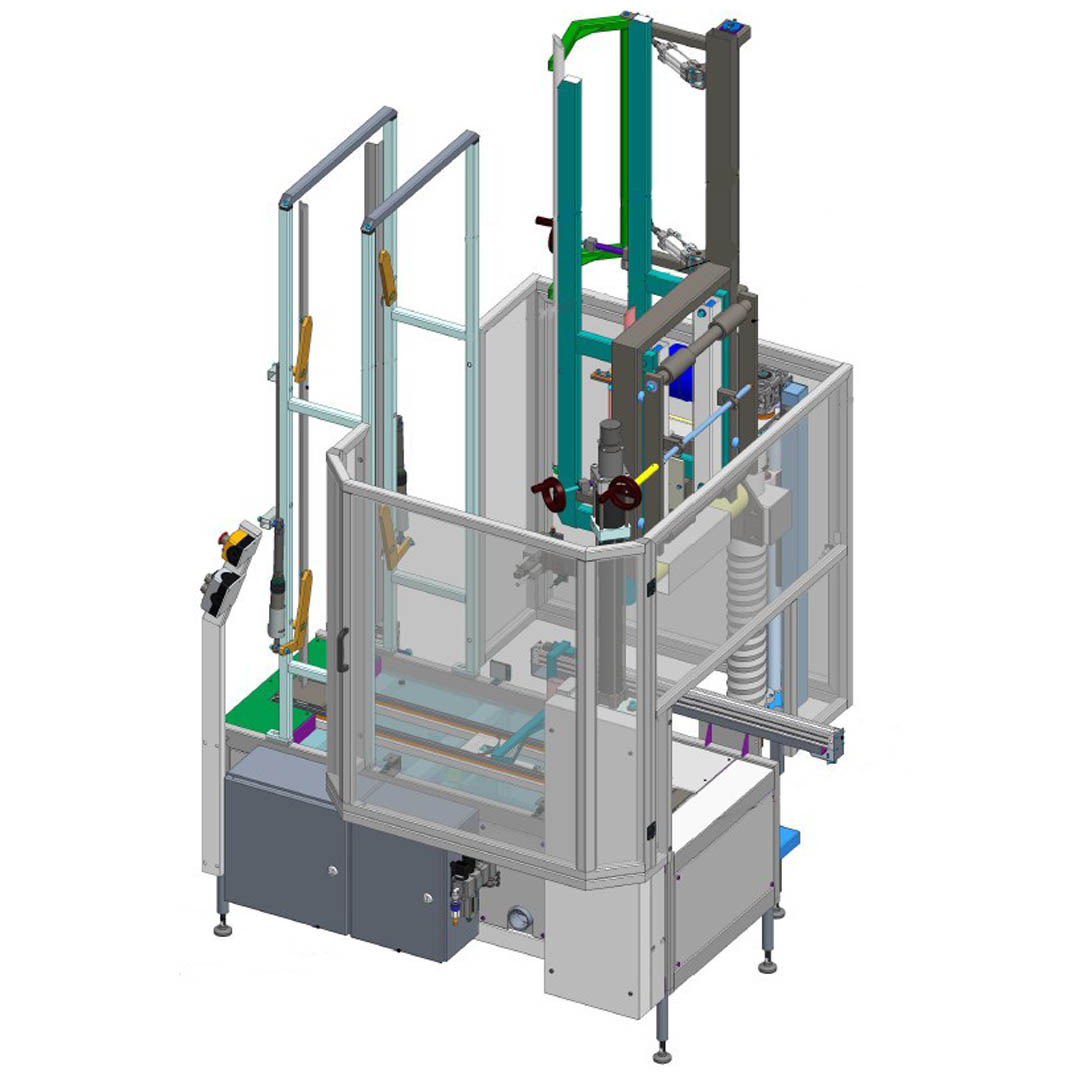

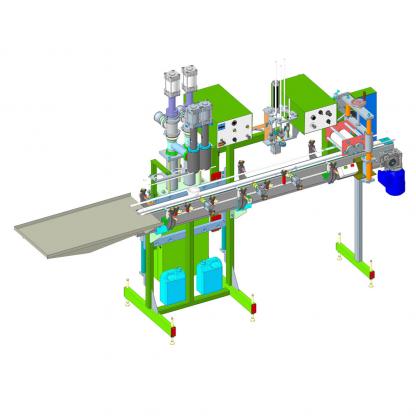

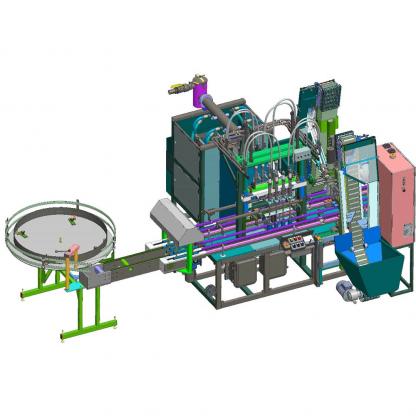

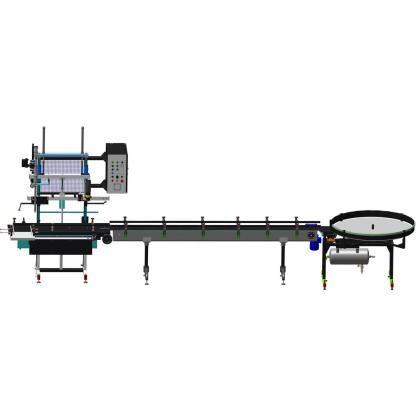

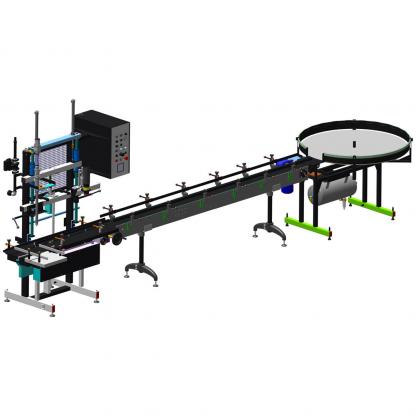

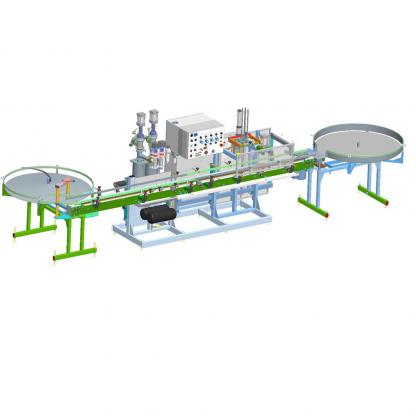

LR.5C Viscous product volumetric filling line for 3 L – 20 L buckets

on order

LR.5C line is intended for stacking, separation and feeding of containers for filling. Container capping and screwing is carried out manually.

LINE COMPONENTS:

1. Automatic unit for container stacking, separation, and feeding.

2. Live roller table w/container travel unit at 90°.

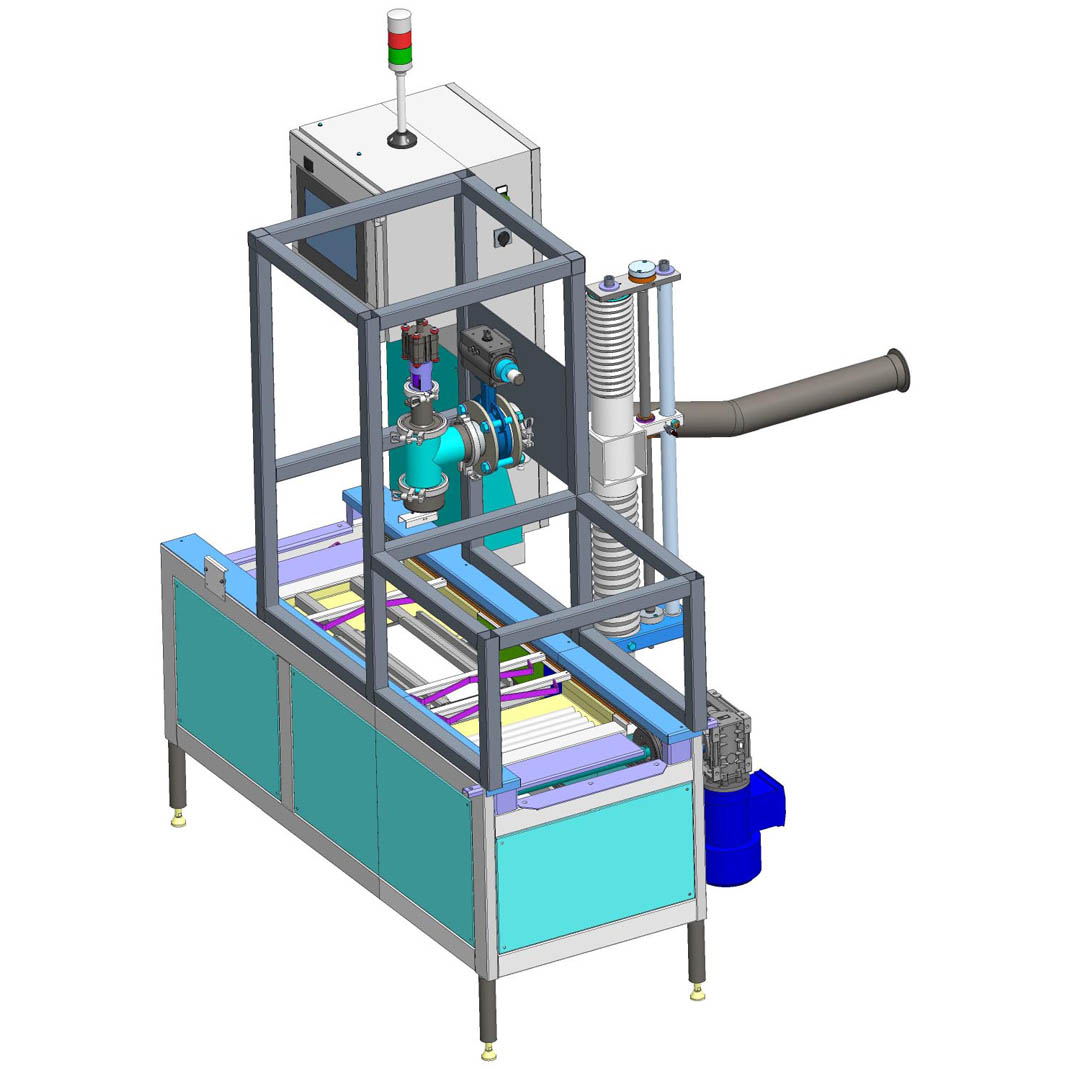

3. Automatic filling unit with one filling position and a containment area.

4. Live angular run-out roller table for filled containers.

The line can be complete with replaceable product feeding routes for quick product change and filling into buckets of various heights.

| Purpose | Filling of organic solvent paints; Filling of organic solvent putties |

| Container | into lug lid metal buckets; into banded metal buckets |

| Dose volume | 5–20 L |

| Filling method | above level filling |

| 1. Filling principle | gravimetric |

| 2. Single dose weight, min. | 2.5kg |

| Single dose weight, max. | 30.0 kg |

| 3. *Capacity, 5 L buckets | 400 pcs/h |

| Capacity, 20 L buckets | 200 pcs/h |

| 4. Dosing tolerance, mean deviation of 10 successive doses | ± 0.5 % |

| 5. Compressed air supply pressure, max. | 6–7 bar |

| 6. Compressed air flow | 30 м3/h |

| 7. Product connection | Flexible metallic hose for 1 MPa, DN=12 mm |

| 8. Product feeding route connection | CLAMP 2” |

| 9. Power supply | 380±38 V, 3 phases, 50±1 Hz |

| 10. Power input | 4.5 kW |

| 11. Load cell | FLINTEKC PC60 |

Related products

- Purpose Filling of water-based paints

- Purpose Filling of water-based putties

- Container into cylindrical plastic buckets

- Purpose Filling of white spirit

- Purpose Filling of solvent

- Purpose Filling of solvents 646, 647, 650

- Container into PET bottles

- Container into plastic jerry cans

- Container into PET bottles

- Purpose Filling of white spirit

- Purpose Filling of solvent

- Purpose Filling of solvents 646, 647, 650

- Purpose Filling of organic solvent paints

- Purpose Filling of organic solvent paints

- Purpose Filling of organic solvent putties

- Container into flat lid tin cans